Crop production, especially grain, is a long-term process. It doesn’t end with harvesting, however, there are still two important tasks to do; properly drying and storing of the products.

Drying is an important step in post-harvest technology because every agricultural product in its natural state contains a certain amount of water, called the moisture percentage. In order to preserve the quality of the product and its storage life, this moisture content needs to be reduced to a level that is safe for storage. Drying is, therefore, a key process for managing the product moisture.

Although drying is one of the oldest methods of food preservation, this is a complex operation which involves heat application over the product. Consequently, the product may change its color, texture, and physical characteristics.

Drying Process and Conditions

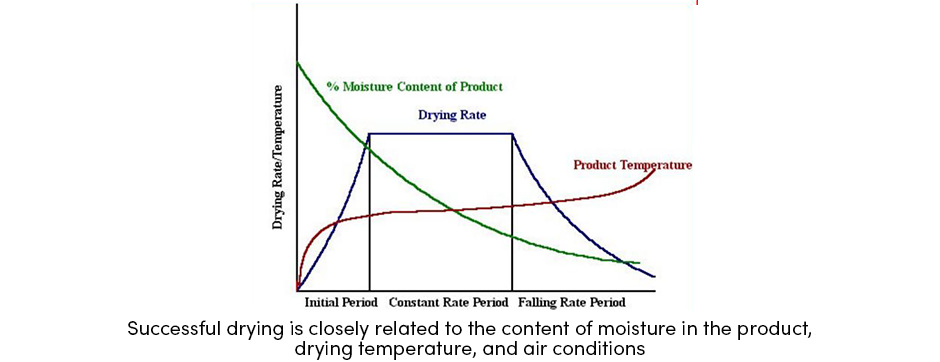

Drying preserves products by removing enough moisture to prevent decay and spoilage. The water content of properly dried products varies from 5 to 25%, depending on the product type. Moreover, successful drying depends on:

- High temperature needed to draw out moisture

- Dry air required to absorb the released moisture

- Adequate air circulation to carry out the moisture

Airflow rate, air temperature, and relative air humidity all together influence drying speed. In general, higher airflow rates, higher air temperatures and lower relative humidity increase drying speed.

Drying speed is also influenced by the content of moisture in the product. For instance, it takes much longer to lower the content of moisture in a product from 25 to 15 percent, than from 35 to 25 percent. This is due to the fact that water present in the outer layers of a product evaporates much faster and more easily than the one in the internal layers. One common misconception is that rapid drying at high temperatures can overcome this problem. In fact, such drying conditions create internal tensions, producing tiny cracks that can lead to ruptures of the product (grains) during the treatment.

In the drying process, the key is to remove moisture from the product as fast as possible, at a temperature that does not seriously affect the flavor, texture, and color. Too low temperature at the beginning can cause the growth of microorganisms, thus affecting its quality. On the other hand, too high temperature in a combination with too low humidity can harden the product’s surface, making it more difficult to dry out.

Finally, delays in drying, incomplete or ineffective drying will reduce product quality and result in losses.

Which Drying System to Choose?

Drying is a very simple, ancient skill. It is one of the most accessible and hence the most widespread processing technology. Here are two common methods used in drying of various products:

- Natural drying; such as sun drying

- Artificial drying; drying with low (aeration) and high temperatures (heated air drying, dryeration, and in-storage cooling)

In natural drying, the product (mainly grains) is spread on the ground, in sun or shade, for a short period. To provide unified drying, the product needs to be regularly stirred. Although this method is simple, it has some limitations—slow drying can harm the product’s quality, therefore it’s not recommended in humid areas due to excessive moisture, and increased relative air humidity at night can speed up dehumidification of the product.

Artificial drying provides faster indoor drying in a controlled environment. The product is exposed to forced ventilation of air, which is heated to a certain degree in special appliances called dryers. Artificial drying is a great solution for faster drying of high-value products as well as preserved product quality. However, purchasing of a dryer, fuel, and other elements necessary for proper work, makes this type of drying expensive and less available to low-income farmers.

As stated, the choice of which drying system to choose depends mainly on the type of crop the farmer grows and his financial ability to afford it.

Classification Criteria of Crop Dryers

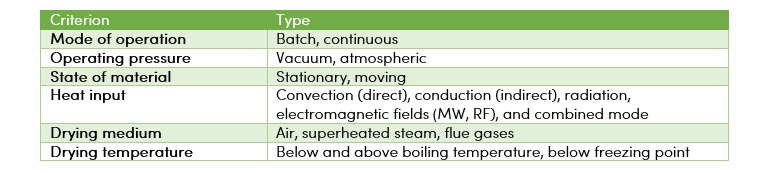

Today, there are over 500 different dryer types known. They all differ on crop type, mode of operation, operating pressure, state of the material, heat input, drying medium as well as on drying temperature.

In the following table are listed all types of dryers based on a certain criterion.

From a scientific point of view, drying is a process of liquid vaporization due to heat application onto the wet product.

Therefore, the byproduct of every drying process is water. The product releases water in two phases. In the first phase, it releases intra-cellular water with nutrients and dissolved solids also called “free water”. As the process continues, the product releases “bound water”. This water is built into cells or biopolymer structures and therefore it needs additional energy to break the bonds with solids.

For safe storage, products must be dried at the appropriate levels and stored under adequate conditions.

Text sources: NDSU || FAO || KMUTT || Scientific & Academic Publishing

Image sources: Keywordhungry || AET Installations. || Agri-Systems