Harvest is one of the most delicate parts of the grain production journey. Grains such as wheat, maize, rice, proso millet, sorghum, and barley play a major role in the human diet. Additionally, grain production is the main source of income for farmers throughout the world. Therefore, all grain farmers share the same goal: to have a plentiful harvest of quality and nutritious grains.

Harvest Machinery: True Support to Every Grain Farmer

Grains are usually harvested with the use of machinery. Manual harvest is rarely practiced in grain production and more common amongst smaller farms that are limited in resources. However, for most grain farmers, suitable harvest machinery can be life-saving. Possessing adequate harvest machinery saves farmers’ time, facilitates the work, and improves efficiency. For this purpose, farmers use different types and sizes of combines. Combines are grain harvest machines named for their ability to perform a few operations in a single pass. The combine is a versatile machine designed to harvest and deliver clean grains that are ready for further processing or storage.

The modern combine market has a quite a story to tell. Today, each combine producer offers many possibilities and different technologies, with a wide range of pricing options. In this regard, combines differ in their construction, operational principle, and additional equipment.

However, there are a few operations common to all combines. These include:

1. Cutting; operation of cutting and collecting the crop

2. Feeding; delivering the crop from the cutting bar to the threshing cylinder

3. Threshing; the process of separating the grain from the stalk

4. Separating; separating the threshed grain from the plant parts that come from the threshing section

5. Cleaning; additional screening of smaller and larger particles such as kernels, chaff, bits of straw, and dirt

6. Discharging the grains in a tank

Brief Overview of Combine Diversity

Although certain models of tractor mounted combines are still available on the market, modern combines are self-propelled machines.

Combine development was particularly affected by the farm technological boom. Therefore, a number of different and more automated combines have been developed in recent years. Modern combines involve additional technological refinements such as complete control over cutting height, hillside adaptation, uniform spreading of leftovers, comfortable and aircondtioned cabine, autosteer system, and yield mapping.

What Is Inside a Combine Harvester?

The exact composition and work principles vary depending on the specific combine type, producer, and type of crop that will be harvested. But generally, all combines consist of the following main components:

- Chassis with engine, fuel tank, wheels or ground power trains, and steering system

- Cabin

- Cutting system- header

- Crop feeding system; spinning augurs and conveyor

- Threshing-separating system

- Cleaning system

- Conveying, storage, and discharge system

The difference between various types of combines is particularly evident within the threshing and cutting systems.

Regarding the threshing system, combines are classified as:

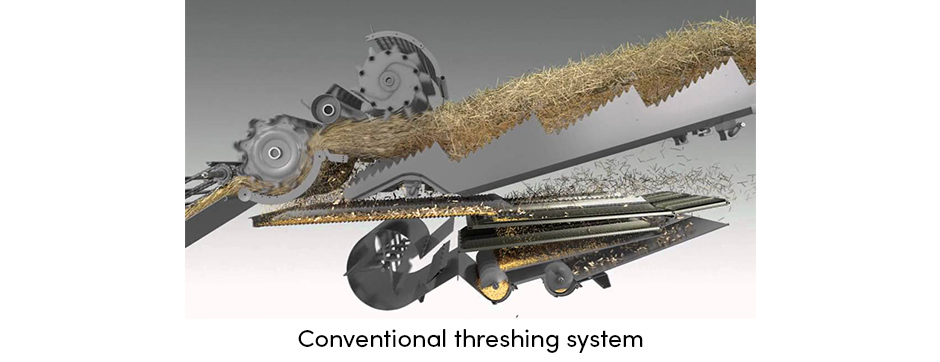

- Conventional; the threshing system within the conventional combines consists of a tangential threshing unit and straw walkers. In the tangential threshing unit, the crop material passes between the rotating threshing drum (also called cylinder) and a concave. The cylinder is positioned transversely within the combine. Threshing and separation occur due to high-speed, under impact of the cylinder bar and concave. Additional separation of remaining grain and straw is performed with straw walkers.

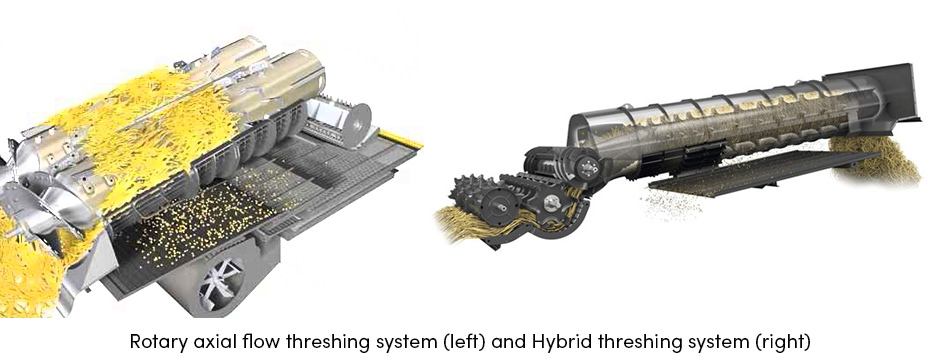

- Rotary (axial flow), crop material flow moves on a helical path between the rotor and a wrapping system of concave and cage.

Additionally, some producers offer a hybrid threshing system that combines both conventional and axial-flow principles of threshing.

Different Types of Cutting System – Headers

Headers are the mechanisms responsible for cutting and collecting the appropriate amount of the plant. There are various types of headers that are suitable for different purposes. However, the two primary types include:

1. Row header; such as the maize header, that includes a number of long snouts arranged in a number of even rows; specially designed to remove only the ear of the plant, thus reducing the possible amount of plant material that would otherwise pass through the combine.

2. Platform header; there are various types available on the market that are suitable for different crops. Regarding the platform header, it’s important to set the cutting height according to the crop demands. Therefore, when harvesting the crop that sets pods along the stem (i.e. soybean), the header platform should be set closer to the ground. On the other hand, when harvesting wheat or rice (crops that produce a single head at the top of the stem), the platform should be set high enough to gather that part of the plant.

Choosing the Best Type of Combine

Due to their cost, complex construction, and various technological possibilities, as well as their remarkable role in harvesting, combines are a serious farm investment. Therefore, when choosing the most appropriate type, a farmer should consider the following aspects:

- Initial price of combine, as well as its maintenance costs

- Combine class; usually dictated by the combine engine power

- Header suitable for specific crop requirements

- Combine performance, the system of combine processing

- The size of a tank

- Crop residue management

- Combine tires and spare parts

- Producer, customer support, and additional services

- Cabin comfort

- Additional possibilities such as auto-steer or yield mapping

More importantly, before considering a combine purchase, a farmer should consider his own needs and financial ability. There are so many things that a farmer should think off. Still, keeping in mind the specific farm and crop requirements is the first serious step towards making the optimal combine choice. After all, once purchased, the combine will definitely facilitate the most delicate farm practice – harvest.

Text sources: Combine Harvesters: Theory, Modeling and Desingn; Petre Miu || Encyclopedia of Agricultural, Food and Biological Engineering; Dennis R. Heldman

Image sources: PrecisionAg || YouTube || YouTube || ALMEX || Sloan Express