Food companies universally dread a product recall. For good reason.

A 2012 survey estimated that U.S. food companies racked up an average of $10 million just in direct costs for things like the logistics of product recall and disposal. Eighteen percent of those companies said they spent an estimated $30 and $99 million in direct recall costs and 5% said they experienced recalls in excess of $100 million. Unreported were indirect costs, such as lost sales, damage to the company’s reputation or legal fees.

While the best way to handle a product recall is to avoid one altogether, it still pays to be prepared with a recall plan in place long before it might be needed, including a recall team, recall process and recall management strategy.

Table of Contents

What is a Product Recall?

A product recall is the actions taken by a company to recall a product because of a default or issue that has created a safety issue for consumers. In most cases, companies voluntarily agree to recall defective products and are responsible for alerting the public, retailers, distributors and manufacturing partners about the recalled product and the imminent safety risk.

Everything from scented candles that burned so hot they shattered their glass holder to pencils marketed to schools and accidentally marked with a slogan encouraging drug use have been recalled. But food products, something we ingest into our bodies, often create the most public concern with the potential to cause devastating harm to a company brand, and even product category damage.

All told, the U.S. Consumer Product Safety Commission (CPSC) issues non-food-related recalls while the Food Safety and Inspection Service (FSIS) of the U.S. Department of Agriculture (USDA) issues recalls on meat, poultry eggs products and the U.S. Food and Drug Administration (FDA) recalls other food items, including pet food. In 2021, there were 47 food product recalls issued affecting more than 15.5 million pounds of U.S. food products. For a current listing of real-time food product recalls, see FoodSafety.Gov.

In the European Union, the Rapid Alert System for Food and Feed (RASFF) coordinates food product recalls while other countries have their own recall policy and procedures. Food companies should be intimately familiar with the food product recall laws and regulatory actions required in the countries they are doing business in the event of a food safety outbreak and product recall.

Classes of Food Recalls

In the U.S. food recalls fall into three different classes. How severe the recall is determined the level of involvement by regulatory authorities as well as the level of response.

Class I Food Recall

The most serious recall, is reserved for food items considered likely to cause serious health events or even death. This may be a product contaminated with a pathogen (like E. coli) or an undeclared allergen.

Class II Food Recall

An item that may cause a temporary health hazard, or a serious adverse health risk is remote. E.g. Norovirus in seafood.

Class III Food Recall

This is a recall that is typically associated with mislabeling or incorrect packaging which violates regulations but is unlikely to cause a health risk. For instance, a product is labeled with the wrong weight. Or as organic when it is not. Most class III food recalls are voluntarily initiated by the food company.

3 Reasons Why You Should Manage a Product Recall

Some companies think that delaying or ignoring the management of a potential recall, especially a recall for a relatively minor issue, will allow the problem to blow over.

In reality, that rarely happens. Delaying or reacting in an unplanned or unmanaged way to a product defect, is doomed to create more problems, more liability and potentially irreparably harm your company’s reputation.

Brand Reputation

Even in the worst case, managing a product recall can preserve the company’s reputation, improve customer satisfaction and help with long-term economic recovery.

This is especially important for food companies. Consumers trust that the products they eat are safe, learning otherwise can fundamentally breach their trust for decades to come. For instance, a 1996 E. coli outbreak in a Washington state apple juice processing facility created lingering distrust in Washington state apple products, especially juice, for years after the contaminated product was recalled and the issues that led to the outbreak were addressed.

Mismanaging a product recall has the potential to make the incident much worse than it would have been otherwise. Especially with the advent of social media, poorly executed product recall management can quickly be whipped into public hysteria causing potentially fatal damage to a brand’s image. As many as 55% of consumers have said they would temporarily switch brands due to a food recall and 15% said they would never purchase the product again.

On the other hand, a well-managed recall and effective crisis management response can not only limit the impact of a food safety event but ultimately build a company’s reputation. How a company handles a food recall can build a bridge to overcome the damage the event itself caused.

Public Health Risk

At the heart of a product recall is a public health risk, something companies should always keep at the forefront when crafting a recall management strategy.

Sometimes companies get so worried about their potential liability that they drag their feet on swiftly and appropriately responding to a product recall. But the longer an unsafe product is in the marketplace the more potential risk it causes. Also, if a company does indeed end up being sued, it puts them in a better position for avoiding punitive damages if they can show the business took the issue seriously and quickly and immediately acted to contain the risk.

Cost of Business

Managing a product recall should be approached with a ‘cost of business’ philosophy. This is an expense that a business incurs in the process of conducting business, how they manage the process can fundamentally affect the potential costs.

When a food recall does occur, there are multiple costs incurred. There is the replacement value of the lost product but there are also many variables depending upon the product and what happened. Labeling and shipment costs, public relations, setting up temporary consumer hotlines, legal fees, food safety consultant fees, extra costs associated with cleaning, sanitation and fixing the problem that lead to the recall as well as any lab fees, fines and even employee overtime are all costs that will likely occur.

How prepared your company is for a recall event can greatly impact the ultimate cost of responding.

Watch our free webinar to learn more about this issue:

10 Steps to Follow in a Food Product Recall

In the event of a product recall, a food company should have in place a plan to respond. The following 10 steps will help a company successfully navigate the stressful days following the issuance of a product recall.

Determine the Cause of the Recall

Once a recall is initiated, the company should submit its recall strategy to the governing authority (in the U.S. this would be the FDA or FSIS). Determining the cause of the recall should be an immediate priority as it is only once the cause is determined that the company can actively move toward fixing the issue and resuming business.

Fix the Issue or Design Flaw

Solve what caused the problem, whether that’s replacing old, faulty equipment, sourcing product from a new supplier or a significant decontamination and clean-up process.

Make sure the issue is, indeed, fixed. Repeated product recalls can be the final death blow to a company struggling to survive a recall event.

Identify Relevant Stakeholders

The food chain is complex. A product recall, especially if the item is used as an ingredient in other products, can affect multiple stakeholders own the food supply chain.

Make sure to identify distribution partners, retail outlets as well as any companies that may be using the recalled item in their products.

Initiate Your Crisis Communication Plan

A crisis communication plan should be set up far in advance of an actual recall incident.

It should consist of why the plan is needed and what the ultimate goal of the plan is, the crisis communication team and their roles, key messages to be relayed during the crisis, the internal communications procedure determining how employees receive information, contacts and media list, and guidelines and checklists to support the process throughout the crisis duration.

Maintain Credibility

Maintaining credibility is a critical goal of any food recall management plan but it can also be a difficult goal to achieve, especially when potential fines and lawsuits are at stake. But, in the long run, honesty and forthrightness will go a long way to repairing the damage of a product recall.

Lean heavily into your crisis communication plan, remembering your key messaging and takeaways. Consider hiring public relations help, even if just to temporarily respond to the crisis.

Issue a Statement and Initiate the Recall

Once a company has learned about a safety issue they need to promptly issue press releases and initiate a recall. Delaying the announcement and recall process can cause significant damage to a brand’s reputation, resulting in fines and even criminal prosecution.

Offer a Refund

Offering a full refund, even for a relatively inexpensive item, goes a long way to restoring consumer confidence in your product and brand. Make sure to set up an information line and create an easy process for requesting the refund.

Handle the Recall Logistics

The recall logistics essentially require you to handle your supply chain in reverse. This includes arranging the shipping of any returns, arranging for pick-up and setting aside warehouse space to hold the product. Make sure to keep the chain of custody reports to properly document that the recalled product was returned.

Plan Product Reintroduction

Product reintroduction can be a delicate matter after a recall, but the efforts you took at the beginning of the process should support a successful reintroduction.

For instance, knowing what or how the issue occurred and having clear documentation of the steps your company took to resolve the issue will build confidence for a successful reintroduction. That said, you still will likely need to reassess your marketing strategy for the product and adjust as needed.

Repair Brand Damage

Repairing brand damage is more complicated than simply stating you’ve resolved the issue and are back in business. Consult with your marketing team and even a public relations consultant to build a strategy for building back brand trust.

6 Steps to Take to Avoid a Product Recall in the Food Industry

While having a recall management plan in place is critical in the unfortunate event of a food product recall, the best strategy for preventing the damage to your business caused by a product recall is to avoid having one in the first place.

Here are six steps to take to limit your recall risks.

Identify Potential Risks and Hazards

Create a vulnerability assessment of your business and processes. Identify any potential areas of concern, for instance where cross-contamination with an allergen might occur or areas that have the potential to introduce pathogens, like washing and packing lines.

Invest in Employee Training

The best food safety system in the world doesn’t do you any good if you’re employees aren’t properly trained on how to use it and then managed to ensure they implement their training. Invest in training systems and task checklists.

Properly Label Everything

Incorrect or missing labeling is often identified as a culprit of product recalls.

Buy Product Recall Insurance

Product recall insurance will help offset the loss of your inventory and cover the costs of implementing recall procedures.

Create a Vetting Process for Suppliers

You risk contamination from suppliers’ products. Institute a vetting process for all your suppliers, such as requesting to see their food safety management plan.

Get the Right Equipment and Use it Properly

Faulty, old or improper equipment can lead to food safety issues.

Total Product Traceability with AGRIVI

Traceability is a powerful new tool farmers, food and retail companies can use for better insight into their supply chain. Traceability helps to manage a recall event when it occurs but also prevents food safety outbreaks from occurring in the first place.

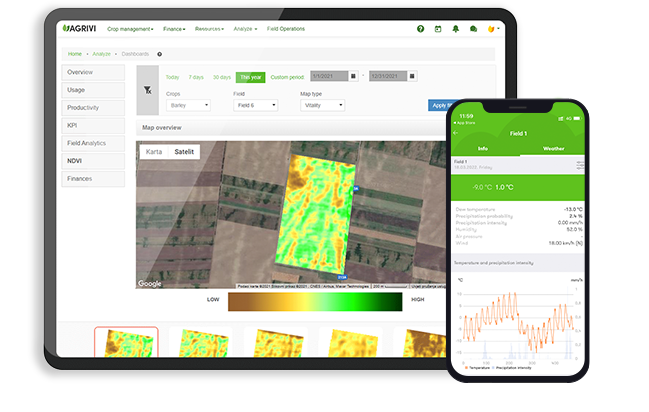

AGRIVI Traceability solution provides complete production traceability through compliance reporting and traceability-based dashboards that allow transparent insight into all farm practices and applied inputs. It offers a comprehensive view of a product’s lifecycle, from planting or harvesting to the end consumer. This includes detailed information on production stages, farming locations, inputs, processes, and quality controls, ensuring product safety and quality.

With AGRIVI Traceability companies can drive consumers’ trust and loyalty by giving them transparent and traceable information about the product lifecycle. AGRIVI generates QR codes which allows companies and their consumers to access traceability data with a simple scan.

By being able to trace the origin of a product and the processes it has undergone, consumers can be sure that the product they are purchasing is safe and of high quality. Read more about why traceability matters: How to Gain Consumers Trust? 4 Key Reasons Why Traceability Matters

For more insight into the steps and strategies, your business can take to avoid outbreaks and food product recalls, download our free Ebook.