Low-density field crops cover a wide range of arable and vegetable crops planted in low-density in order to enable interrow cultivation. Such crops include sugarcane, potato, and various leaf and root vegetables. These crops are significant to human diet improvement, as well as for beverage and industrial production. Therefore, growing low-density field crops is actually a very important and profitable business.

Because planting (or sowing) marks the actual beginning of the crop life-cycle, it’s a farm practice that is critical to managing low-density crop production. In order to manage it properly from the early beginnings, farmers use different planting or sowing machines. Generally, each crop has its own farm management and machinery requirements. Therefore, an access to suitable farm machinery significantly facilitates one of the most stressful crop production stages. This is the actual crop life-cycle beginning.

Common Features of All Types of Planting Machines

When describing planting machinery used for low-density field crops, it’s important to keep in mind that these crops differ greatly. Some of them are sown, while others are planted or transplanted. In addition, each crop and each field, as well as each crop production type, have their own farm machinery requirements. However, there are still some characteristics of planting machinery that are common amongst all aforementioned categories. Each planting machine is designed and produced to perform the following functions:

- Open a furrow in the soil

- Meter the seeds/seedlings at a specific rate

- Deliver the seeds/seedlings at a desired depth

- Keep a certain spacing between the seeds/seedlings

- Cover the seeds/seedlings with soil.

Various Possibilities of Planting Machinery

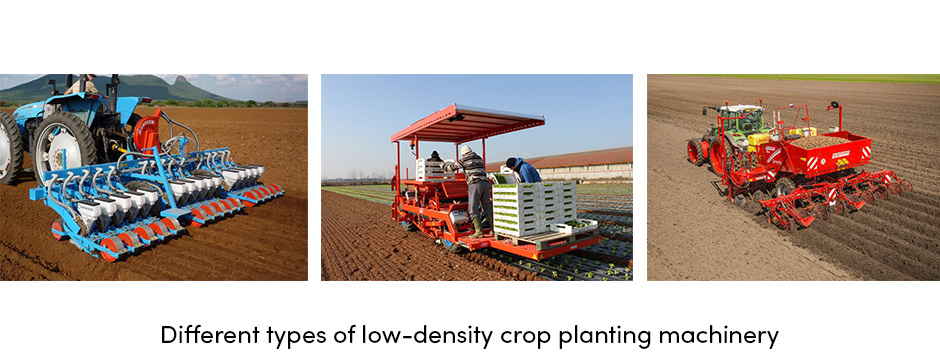

Today’s farm technology is experiencing a peak related to its remarkable development, revealing special possibilities. However, we still live in a world where farms less than 1 hectare account for 72% of all farms. Most of these smallholder farmers are unaware of all of the possibilities of modern planting machines. Unfortunately, there are many farmers worldwide that still use simple manual or animal-driven planting machines.

Mechanized planting machines also differ depending on their attachment to a tractor. This classification includes the following groups:

- Mounted

- Semi-mounted

- Trailed

- Self-propelled.

Moreover, there are also machines intended for sowing of low-density field crops. The row seeder, for instance, deposits the seeds into rows, thus leaving space to permit interrow cultivation. Additionally, row seeders can be used with many attachments for fertilizer or chemical application.

Another category inclusive of low-density field crop planting machines are the no-till planters/ sowing machines. They differ from each other in what the machine is intended for (sowing, planting or transplanting), as well as in some additional attachments and properties. However, there is one thing common to all no-till planters; they cut through the soil and crop residues while at the same time creating the furrow and placing the seed or seedling. After the seed or seedling is placed, another part of the no-till planter closes the furrow.

Low-density field crop planting machines differ in the crop planting requirements. For example, various planters have been developed according to specific crop requirements, such as the following three types:

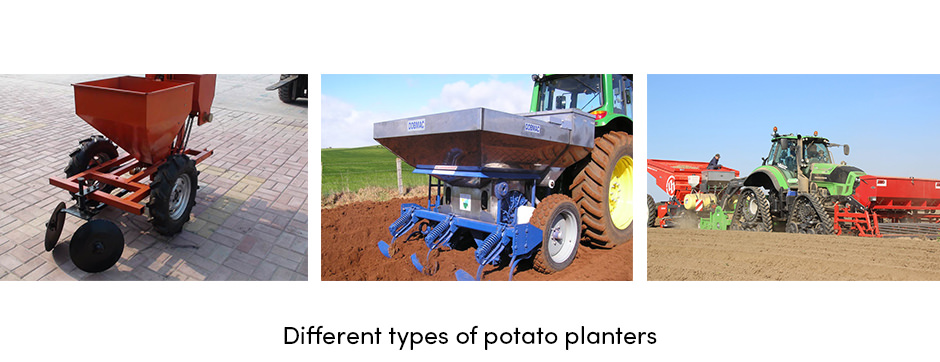

1. Potato planters

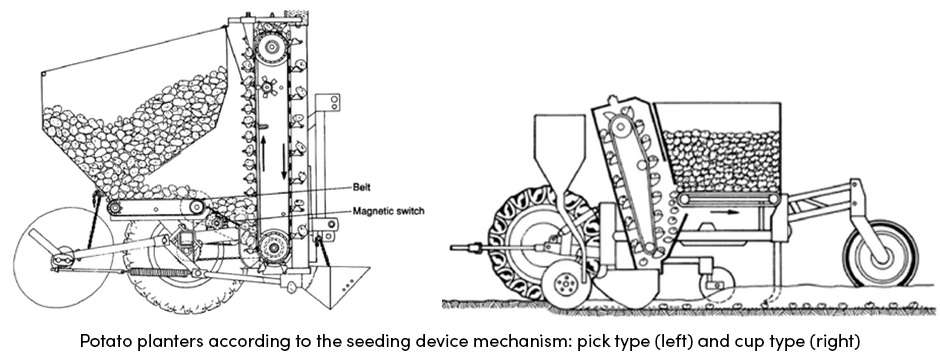

There are many types of potato planters available. Regarding the seeding device mechanism, farmers mainly use cup- or pick-type planters. Cup planters move seed tubers from a hoper into a furrow with the help of small cups. Pick-type planters include a nail-like mechanism that picks potato seeds from the hopper and drops the seeds into the furrow being plowed.

Potato planters range from small and simple machines to modern, fully equipped planters appropriate for managing the planting of large-scale farms.

2. Sugarcane planters

Since sugarcane is usually grown in developing countries, farmers mostly use simple planting machinery, such as the simple mechanical sugarcane planter. Today, though, there are various improved and modern sugarcane planters that are available. However, these are more appropriate for large-scale farmers that are not limited in resources.

3. Leaf and root vegetable transplanters

These planters are usually self-propelled or tractor trailed. Regarding the main principle of working, there are the two different types of vegetable transplanters:

- Semi-automatic; seedlings are delivered manually; the operator selects a seedling and distributes it further into a planting mechanism that delivers the seedling into the soil

- Automatic; seedlings are delivered automatically by the machine itself; when compared to semi-automatic, these transplanters are faster and labor-saving.

Outside of the semi-automatic and automatic transplanters, some farmers, particularly small-holder and family farmers, use manual vegetable transplanters. However, farmers who can afford automatic or at least semi-automatic transplanters manage their transplanting much easier. Additionally, vegetable transplanters may contain plastic or biodegradable mulch cover.

Each low-density field crop has its own requirements for the specific type of planting machinery. Farmers often use planting machinery that fits the specific crop and field requirements and fits into their budget. After all, the beauty of farming is in its true diversity provided by many different choices.